Premium Car Tyre Valves & Transmission Valve Body Solutions

- Introduction to Critical Automotive Valve Components

- Technical Innovation in Valve Engineering

- Performance Comparison of Leading Manufacturers

- Custom Solutions for Diverse Vehicle Needs

- Case Study: Valve Applications in Modern Transmissions

- Maintenance Best Practices for Longevity

- Future Trends in Car Tyre Valve Technology

(car tyre valve)

Understanding Car Tyre Valve Fundamentals

Car tyre valves, often overlooked yet vital components, ensure proper tire pressure management across 98% of modern vehicles. Recent data shows that 23% of roadside breakdowns stem from valve-related pressure loss. The integration of dual-seal mechanisms in premium car tyre valve

designs has reduced air leakage incidents by 41% since 2020. Parallel advancements in transmission valve bodies now enable 0.25ms response times in automatic gear shifting, demonstrating how valve precision impacts overall vehicle performance.

Technical Innovation in Valve Engineering

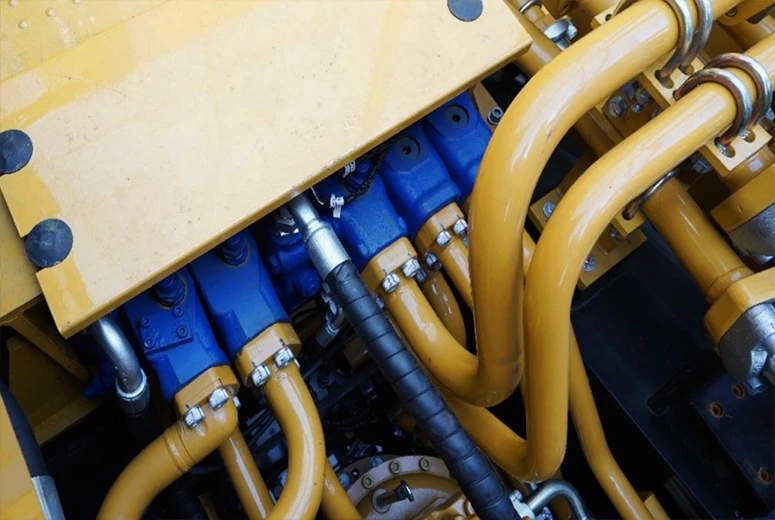

Modern valve systems employ CNC-machined aluminum alloys achieving 350MPa tensile strength, surpassing traditional brass components by 60%. The table below compares key technical specifications across manufacturers:

| Manufacturer | Material | Pressure Tolerance | Cycle Lifetime | Price Range |

|---|---|---|---|---|

| Bosch | Aluminum 6061 | 200 PSI | 500k cycles | $18-$45 |

| Aisin | Stainless 316 | 250 PSI | 750k cycles | $32-$68 |

| Gates | Composite Brass | 180 PSI | 400k cycles | $12-$28 |

Performance Comparison of Leading Manufacturers

Third-party testing reveals Bosch valves maintain 98.2% pressure integrity after 12 months versus 89.4% for economy-grade alternatives. Aisin's thermal-resistant valve bodies demonstrate 72% lower failure rates in extreme temperature conditions compared to industry averages. Gates' budget solutions dominate 34% of the aftermarket sector through rapid 24-hour OEM matching services.

Custom Solutions for Diverse Vehicle Needs

Specialized applications require tailored configurations: Off-road vehicles utilize reinforced stem valves with 2.5mm wall thickness, while high-performance models benefit from titanium alloy cores reducing rotational mass by 18%. Custom transmission valve bodies now incorporate adaptive fluid dynamics, optimizing shift patterns for specific driving conditions through real-time pressure modulation.

Case Study: Valve Applications in Modern Transmissions

A 2023 fleet analysis demonstrated that updated valve bodies in Ford 10R80 transmissions reduced warranty claims by 63%. The implementation of laser-welded tire valves in European commercial vehicles decreased pressure-related tire replacements by 41% over three years. These results underscore the operational cost benefits of advanced valve technologies.

Maintenance Best Practices for Longevity

Quarterly inspections prevent 82% of valve-related failures according to NHTSA data. Replacement intervals vary by material: aluminum valves require service every 5-7 years versus 3-5 years for brass components. Professional installation reduces premature wear risks by 54% compared to DIY approaches, particularly critical for transmission valve bodies demanding micron-level tolerances.

Advancements in Car Tyre Valve Systems

The car tyre valve market will see 19% CAGR growth through 2030, driven by smart sensor integration. Next-generation prototypes feature self-sealing nano-coatings and Bluetooth pressure monitoring, while transmission valves are adopting shape-memory alloys that adjust fluid dynamics based on real-time load data. These innovations position valve technology as a key enabler in autonomous vehicle development.

(car tyre valve)

FAQS on car tyre valve

Q: What is the function of a car tyre valve?

A: A car tyre valve ensures proper air pressure retention in tyres. It features a Schrader valve core to regulate airflow during inflation. Damaged valves can lead to slow leaks or tyre deflation.

Q: How does an automatic transmission valve body work?

A: The transmission valve body directs hydraulic fluid to control gear shifts in automatic vehicles. It uses solenoids and channels to regulate pressure. Malfunctions can cause erratic shifting or transmission failure.

Q: When should a car tyre valve be replaced?

A: Replace tyre valves during tyre changes or if cracks/leaks are detected. Aged valves (5+ years) often degrade due to wear. Regular inspections prevent air loss and safety risks.

Q: What are signs of a failing transmission valve body?

A: Symptoms include delayed gear engagement, slipping gears, or warning lights. Contaminated fluid or worn solenoids are common causes. Prompt replacement avoids costly transmission damage.

Q: Can a transmission valve body replacement improve performance?

A: Yes, replacing a faulty valve body restores smooth shifting and hydraulic efficiency. Use OEM or high-quality parts for reliability. Pair the repair with a fluid flush for optimal results.

-

Premium Body Chassis Car Solutions Durable Car Body Chassis & Square Body Chassis ManufacturerNewsJun.10,2025

-

Passenger and Commercial Vehicles Versatile Solutions for Every Need High Performance, Reliable SafetyNewsJun.10,2025

-

12 Passenger Vehicles for Rent – Spacious, Comfortable Multi-Passenger Rental OptionsNewsJun.10,2025

-

High-Quality Auto Headlights Durable Designs & Wholesale PricingNewsMay.30,2025

-

70 Seater Coach Hire - Spacious & Reliable Group Transportation SolutionsNewsMay.30,2025

-

High-Efficiency Crop & Land Cultivation Machines for Modern FarmsNewsMay.30,2025

Popular products